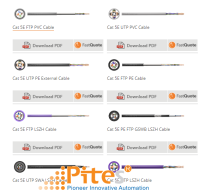

Thiết bị cảm biến đo chỉ tiêu nuôi trồng thủy sản 5200A Multiparameter YSI pitesco Vietnam

Xuất sứ: USA

Nhà cung cấp: PITESCO

Hãng sản xuất: YSI

Thiết bị cảm biến đo chỉ tiêu nuôi trồng thủy sản 5200A Multiparameter YSI pitesco Vietnam

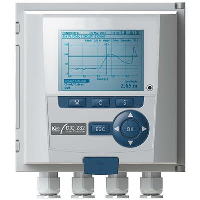

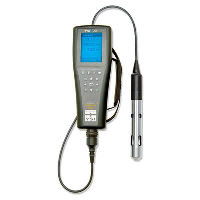

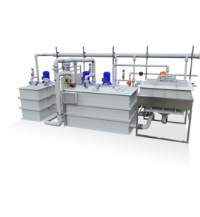

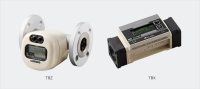

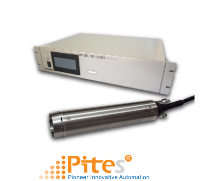

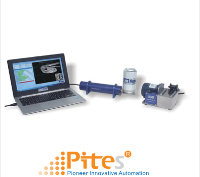

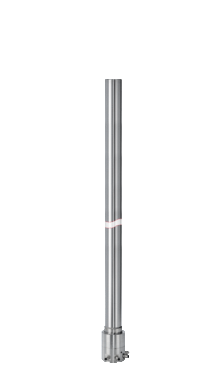

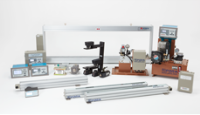

Designed specifically for Aquaculture Systems, the YSI 5200A and AquaManager™ Software integrate process control, alarming, and data management into one product. Simple enough to monitor one tank, powerful enough to manage a full scale farming operation from anywhere in the world. Simultaneously measure dissolved oxygen, pH, conductivity, ORP, salinity and temperature.

Engineered specifically for recirculating aquaculture systems, the YSI 5200A continuous monitor and AquaManager® Software can be used to integrate process control, feeding, alarming, and data management into one product or can be used to simply monitor one tank. Powerful enough to manage a full scale farming operation from anywhere in the world yet simple enough for anyone to use.

Access your facilities water quality data at any time with the AquaViewer App from the App Store or manage your network with AquaManager desktop software.

- Multiparameter monitor: DO, Temperature, Conductivity, pH, ORP, Salinity

- Ethernet TCP/IP or wireless communications

- Event logging records calibrations, high and low conditions and more

- Conditional feed timer with Feed Smart software included

- Networking capability up to 32 instruments per comm port or can be integrated with 5400 Multi DO monitors

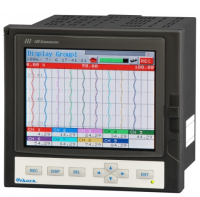

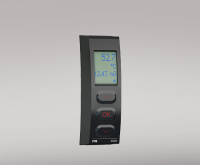

- Graphic, backlit LCD - quick, reliable system status checks

- Plug-and-play...easy to install and maintain with user-scalability - no need to hire consultants

- Flexible monitoring and control software

- Email and SMS alarming

Feed Smart software manages food delivery based on user-selectable inputs to manage feed delivery based on number of daily feedings, daily feed weights, total biomass and FCRs, along with parameter control based on water quality values. interfaces with most auto feeders.

AquaManager desktop software provides the ability to instantly see an overview of your facility, manage parameter set points, and conveniently manage data to make informed operation decisions. If you're interested in a continuous monitor for dissolved oxygen, please visit the 5500D (optical dissolved oxygen) or 5400 (galvanic dissolved oxygen) page.

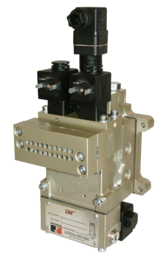

The YSI IOEM and REM expansion modules increase the flexibility and capability of the YSI aquaculture platform when networked with 5200A, 5400 or 5500D instruments. Configure 4 (IOEM-4) or 8 (IOEM-8) analog channels as inputs or outputs for the ability to integrate 3rd party sensors or output from other devices. Outputs can be configured to control pumps, UV systems, analog valves, or send data to SCADA/ PLC systems. REMs (Relay Expansion Module) add relays where needed to control feeders, lighting, heaters, alarming, and more.

Thiết bị cảm biến đo chỉ tiêu nuôi trồng thủy sản 5200A Multiparameter YSI pitesco Vietnam

|

Buffer Recognition |

Yes |

|

Certifications |

RoHS, IP-65, ETL, CUL, NEMA 4X, CE, Made in USA, ULC |

|

Connectivity / Communications |

Ethernet and wireless optional. Output Relays: 4 each 10 amp 115 VAC (5 amp 230 VAC) relays for parameter, control and/or alarm E-mail and/or SMS alarming up to 3 e-mails with Ethernet module or up to 10 e-mails with AquaMana, RS-485 and RS-232 standard |

|

Data Management |

AquaManager™ Software integrates process control, alarming, and data management into one product |

|

Desktop Software Compatible |

Windows 2000/XP/Vista/Windows 7 operating systems, AquaManager® |

|

Display |

Back-lit graphic LCD (320 x 240) with timer, extended temperature range LCD |

|

Equipment used with |

or 30, 10, 5561-4, 20, or 20, AquaManager Desktop Software, 5562-4 |

|

GLP Compliance |

Yes |

|

Logging Capabilities |

Yes |

|

Measurement Method / Channels |

DO, pH, ORP, conductivity, temperature, 2 user-configurable inputs, digital (0 to 1.0 VDC, 0 to 5.0 VDC or 4-20 mA) Timers: 4 timers - 10 events cascading events start/duration 1 feed timer channel (feeder not included), Feed Smart software manages feed |

|

Memory |

Non-volatile, 1000 data, 1250 relay/alarm, 1000 entries/change and 500 GLP records |

|

Monitoring |

Yes |

|

Multiparameter |

Yes |

|

Operating Temperature |

-15 to +70°C (5 to 158°F), direct outside conditions with NEMA 4X enclosure |

|

Parameters Measured |

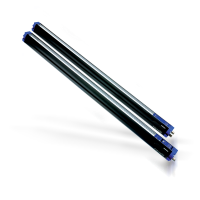

Dissolved Oxygen (electrochemical), pH,ORP/Redox, Conductivity, Specific Conductance, Salinity, Total Dissolved Solids (TDS), Temperature |

|

Power |

12 V DC, mobile live haul or anytime AC power not available |

|

User Calibratable |

Yes |

|

User Replaceable |

Yes |

|

Warranty |

2-years instrument; 1-year probes and cable |

|

Waterproof |

Yes |

|

Specification |

|

|---|---|

|

Timers |

4 timers - 10 events cascading events start/duration |

|

Field Upgradeable Software |

Yes; flash based |

|

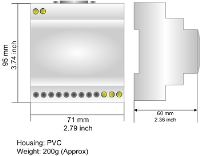

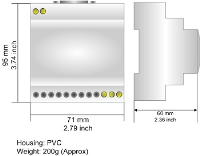

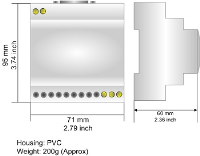

Height |

6.5 in, 16.5 cm |

|

Length |

8.5 in, 21.6 cm |

|

Depth |

4.75 in, 12.1 cm |

|

Parameter |

Range |

Accuracy |

Resolution |

|---|---|---|---|

|

Dissolved Oxygen* |

0 to 500% |

0 to 200%: ±2% or ±0.2 mg/L, whichever is greater; |

0.1% air saturation |

|

Dissolved Oxygen* |

0 to 60 mg/L |

0 to 20 mg/L: ± 0.2 mg/L or ±2% of reading, whichever is greater; |

0 to 10 mg/L: 0.01 mg/L |

|

Temperature |

0 to +45°C (32 to 113°F) |

±0.2°C |

0.1°C |

|

Conductivity |

0 to 200 µS; |

0 to 100 mS: ±0.5% of range |

0.1 µS |

|

Salinity |

0 to 80 ppt (0 to 50 ppt when entered manually) |

±2% or ±0.1 ppt, |

0.1 ppt |

|

pH |

0 to 14 units |

±0.2 units |

0.01 units |

|

ORP |

-2000 to +2000 mV |

±20 mV |

1 mV |

*Polarographic dissolved oxygen sensor

Specifications indicate typical performance and are subject to change.