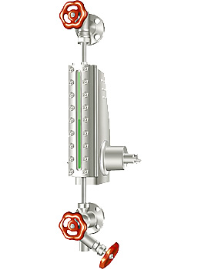

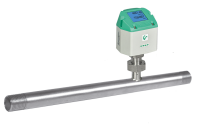

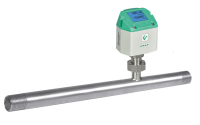

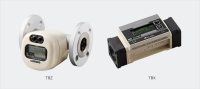

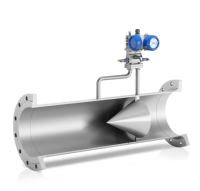

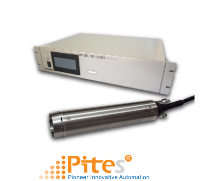

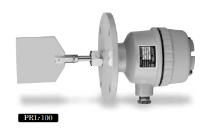

ACONE Cone Differential Pressure Meter Smartmeasurement Vietnam, Đồng hồ đo áp suất chênh lệch hình nón Smartmeasurement Vietnam, phân phối chính hãng Smartmeasurement Vietnam

Nhà cung cấp: pites

Hãng sản xuất: Smartmeasurement

Cone Differential Pressure Meter Smartmeasurement Vietnam, Đồng hồ đo áp suất chênh lệch hình nón Smartmeasurement Vietnam, phân phối chính hãng Smartmeasurement Vietnam

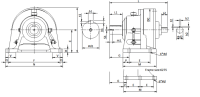

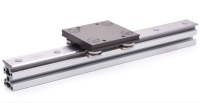

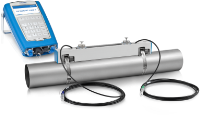

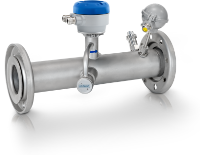

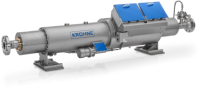

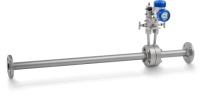

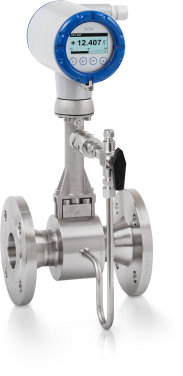

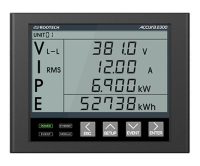

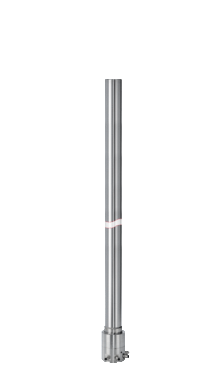

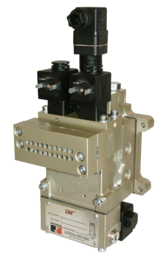

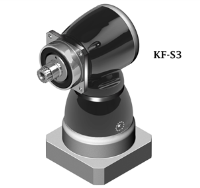

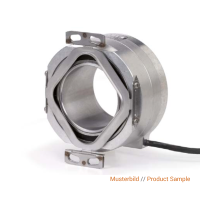

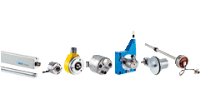

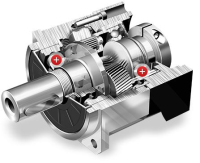

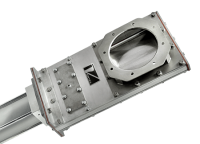

SmartMeasurement’s ACONE differential pressure flowmeter is designed for the harshest operating environments and the widest variety of fluids. This sensor consistently out-performs traditional ΔP devices and other major flow technologies. The ACONE's enhanced performance is due to the shape and position of a fixed-cone inside of the flow body in relation to the ΔP measurement ports. The cone interacts with the flow, reshaping the fluid's velocity profile and creating a region of lower pressure immediately downstream of itself. Two pressure taps are designed to measure the differential pressure between the static line pressure and the low-pressure zone created downstream of the cone. Flow is calculated by the Bernoulli equation of conservation of energy. The cone shape also acts as its own flow conditioner, fully conditioning any turbulence in flow due to limited upstream and downstream straight runs. The ACONE is a primary element – it may be used in conjunction with third-party differential pressure transducers or with pressure transmitters supplied by SmartMeasurement. It is available in sizes ranging from ½” to 120” with a number of available options for process connections and materials of construction. The ACONE’s high performance, combined with its wide array of available features and relative low cost make it a superior value versus other differential-pressure based flow measuring technologies.

- High accuracy and repeatability

- Conditions flow before measuring

- Minimal straight pipe requirements

- Very wide selection of sizes - ½"~120" (15~3000mm)

- Lower pressure loss than most other flow measuring technologies

- Can measure clean or dirty liquids, slurries, gases and steam

- Low signal noise

- Anti-fouling, non-clogging design

- Will accommodate multiphase flows

- Good particle tolerance; not sensitive to suspended contaminents