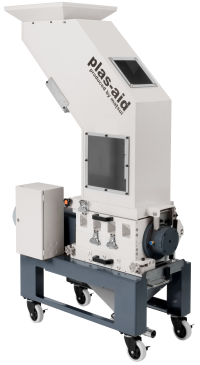

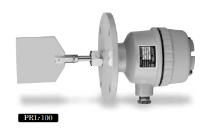

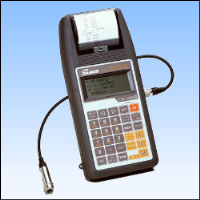

PPT3000-AL Agr Vietnam, PPT3000-AL-Agr International Vietnam

Nhà cung cấp: Pitesco

Hãng sản xuất: AGR Vietnam

PPT3000-AL Agr Vietnam, PPT3000-AL-Agr International Vietnam, đại lý Agr International Vietnam

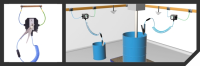

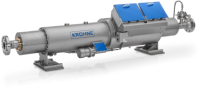

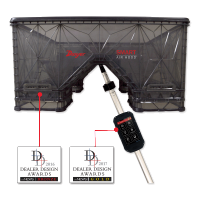

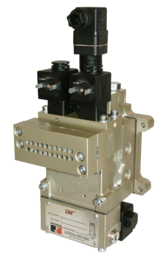

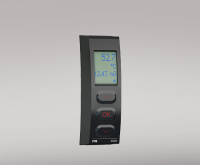

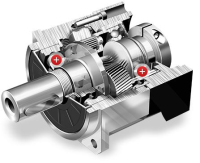

The PPT3000-AL is designed for the unique testing requirements of today’s light-weight aluminum bottles. This version offers a dual-pressure testing mode with high-resolution, servo-controlled pressure and volume expansion testing capabilities that make it possible to perform high precision buckle or dome tests on aluminum bottles as well as traditional plastic pressure tests. This version is ideal for beverage producers that work with aluminum bottle manufacturers as well as filling operations that process aluminum and plastic containers in the same facility.

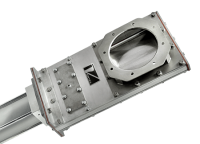

Buckle/dome testing

This test mode applies controlled internal pressure to a container to the point of base failure. The pressure level at which this occurs is tracked by the PPT3000 system, capturing the pressure value, elapsed time and volume expansion at the point of failure. The pressure/volume test-curve is displayed on the user interface with all final test results.

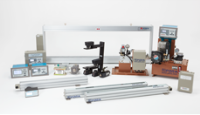

Testing capabilities

Aluminum bottle testing — Predefined 2-stage, test routine with the following:

- Operator definable pressure profile (loading rates and end points)

- Ability to end test at buckle or continue through to burst/end point

- Algorithms for automatic determination of:

- BP buckle point pressure

- BPV – buckle point volume expansions

- BV – buckle volume expansion

Plastic bottle testing

- Fill-Ramp Mode – simulates the conditions for filling operations

- Burst Pressure Mode – pressurized quickly to a predefined pressure level

- Custom Test Mode – provides the capability to create unique profiles

- M-RULE® Shelf-Life Mode (optional) – provides material utilization and predicted shelf-life data

Features

- Integrated variable pressure programmability

- High resolution volume expansion measurement

- Water temperature monitoring

- Pressure and volume expansion curves displayed during the test

- Operator input for mold number and end of test results

- Ability to set upper and lower control limits

- Integrated M-RULE® Shelf-Life prediction module (optional)

Product Brochure