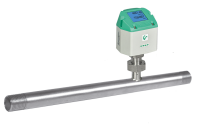

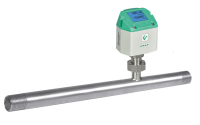

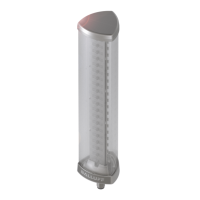

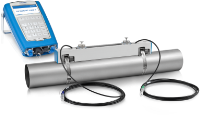

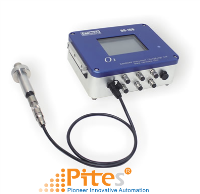

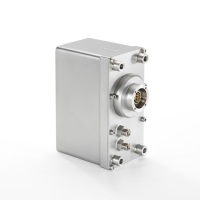

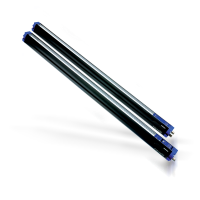

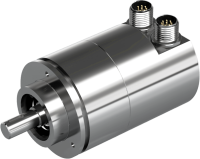

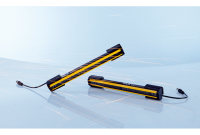

Displacement measurement sensors OD Mini, Cảm biến đo dịch chuyển OD Mini Sick YSI VietNam.

Nhà cung cấp: Pitesco

Hãng sản xuất: Sick

OD1-B150F0AQ14, Displacement measurement sensors OD Mini, Cảm biến đo dịch chuyển OD Mini Sick YSI VietNam.

Your Benefits

- Cost-saving commissioning through simple operating concept and display

- Small installation size and low weight also allow use in highly dynamic applications

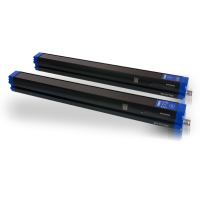

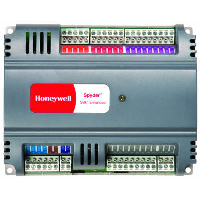

- Calculation of two sensorheads - easy possible over the external evaluation unit

- High machine throughput thanks to reliable measurement, regardless of brightness and color of surface

- The wide range of available interfaces enables simple integration into industrial networks

- Optimum performance even at high production speeds

OVERVIEW

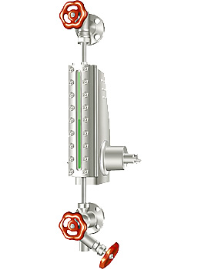

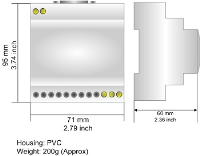

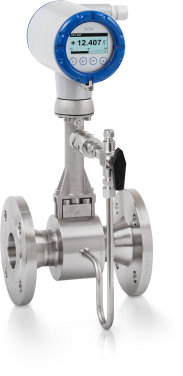

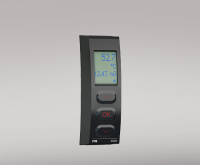

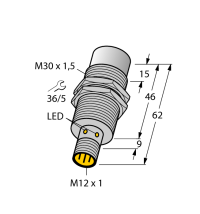

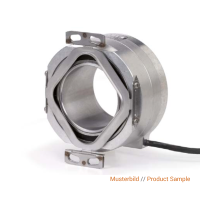

Simple, precise, and economic solutions for measuring tasks, the OD Mini displacement measurement sensors are impressive with their compact and rugged housing, which is available in a lightweight aluminum or a rugged stainless steel. These sensors are equipped with the latest CMOS receiver technology for precise measurement, regardless of the brightness and color of the surface material. The integrated amplifier unit enables the OD Mini to work on a stand-alone basis. For complex measurement tasks up to two OD Mini Pro sensor heads can be connected to one OD Mini evaluation unit and calculate together. The OD Mini is simple to configure due to its intuitive design and display with four status LEDs. The OD Mini can also be remotely programmed via the external teaching input. The large number of available interfaces also simplifies integration into industrial networks. This ensures the highest possible reliability and precision when solving a wide range of measurement tasks.

- Compact, rugged housing

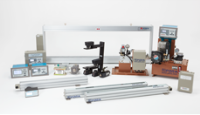

- Stand-alone use or in combination with the OD Mini evaluation unit

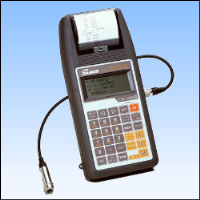

- Display and LEDs on device for visualization of current status

- Different interfaces available

- Simple teach-in using display or external teaching input

- CMOS receiver unit for precise, fast measurement in the µm range

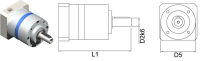

- Various measuring ranges: Measuring from 10 mm to 250 mm possible

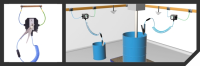

APPLICATIONS

TECHNICAL OVERVIEW

-

Technical data overview

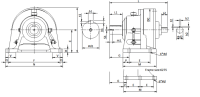

Measuring range 10 mm ... 250 mm Linearity ± 10 µm ... ± 100 µm Repeatability ≥ 20 µm 1) 2) 3)

≥ 200 µm 1) 3) 4)

1 µm ... 20 µm 1) 3)

Response time ≥ 2 ms 5) Measuring frequency ≤ 2 kHz Switching output 1 x PNP/NPN, selectable

2 x PNP/NPN, selectable

3 x PNP/NPN, selectable

Serial ✔ , RS-485 PROFIBUS DP ✔ , optional, over external evaluation unit Analog output 1 x 4 mA ... 20 mA (≤ 300 Ω)

1 x 0 V ... 10 V (> 10 kΩ)

1 x 4 mA ... 20 mA (≤ 300 Ω) 6)

Ambient temperature operation –10 °C ... +50 °C Ambient storage temperature –20 °C ... +60 °C - 1) Averaging function set to: 512.

- 2) Hysteresis 0.08 mm.

- 3) Constant ambient conditions.

- 4) Hysteresis 0.8 mm.

- 5) With fixed sensitivity adjustment and averaging setting = 1. With automatic sensitivity and measuring rate 500 µs: 2 ... 7.5 ms response time/measuring rate 1,000 µs: 4 ... 15 ms response time.

- 6) Optional over evaluation unit AOD1.