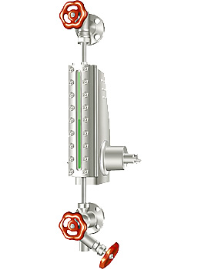

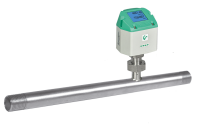

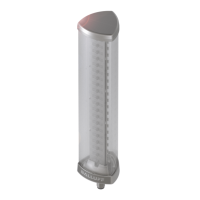

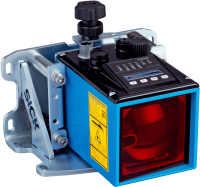

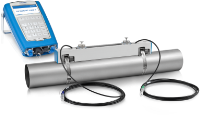

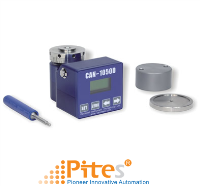

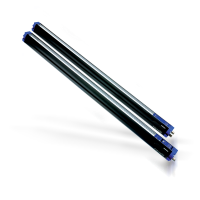

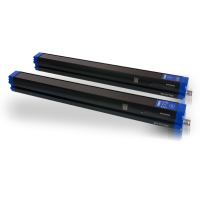

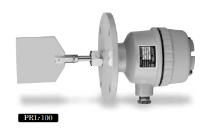

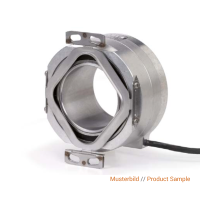

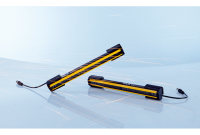

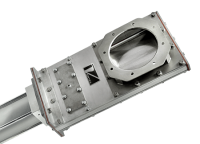

Displacement measurement sensors Profiler, Cảm biến đo lường dịch chuyển Sick YSI VietNam.

Nhà cung cấp: Pitesco

Hãng sản xuất: Sick

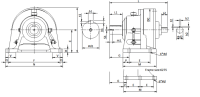

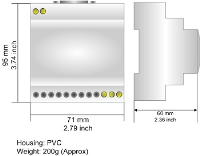

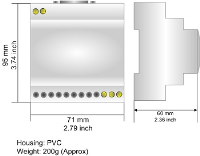

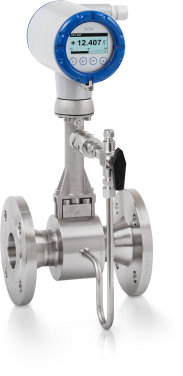

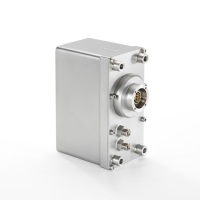

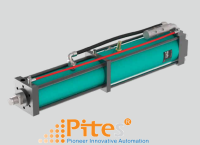

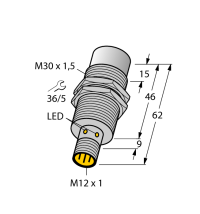

PRO2-N100B25A1, Displacement measurement sensors Profiler, Cảm biến đo lường dịch chuyển Sick YSI VietNam.

Your Benefits

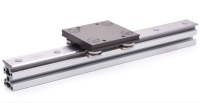

- Measuring a 2D profile with just one sensor saves on hardware and installation costs

- Cost-effective solution for 2D profile measurement

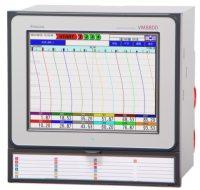

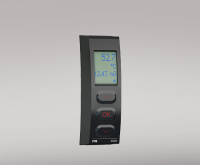

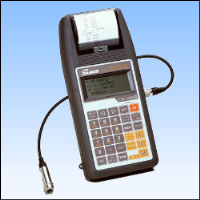

- Real-time visualization of the measurement results via the integrated LC display

- Intuitive and quick commissioning via the software or display reduces installation time

- Thanks to the stand-alone concept of the Profiler 2, there is no need for cabling or to mount an additional evaluation unit

- Reliable measuring regardless of color, material, or shape

- More than 10 integrated measurement functions allow profiles to be measured and analyzed quickly

OVERVIEW

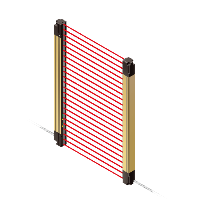

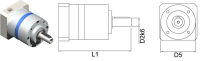

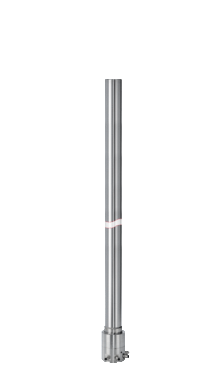

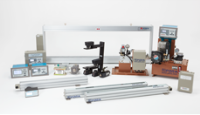

The Profiler 2 displacement measurement sensor performs highly accurate measurements on the x and z axes and can also measure the surface of more complex objects. Up to four areas can be analyzed at the same time with a single measurement. One of the 10 integrated measurement functions, e.g., height or width, can be selected for each area. The integrated evaluation unit of the Profiler 2 saves you time and money when it comes to installation – making the sensor one of the most cost-effective solutions for profile measurement. While the integrated CMOS receiver unit guarantees precise measuring, the supplied software makes commissioning simple and provides exceptional visualization of the measurement process. The integrated LC display offers real-time visualization.

- Measure complex profiles with just one laser line

- Analyze up to four areas at the same time

- More than 10 integrated measurement functions, e.g., height, width, and inclination

- Sensor head and evaluation unit in one device

- Commissioning via software or integrated display with operating elements

- High-quality CMOS receiver unit